While LCA is a part of making the right decisions in reducing the environmental impact of a construction project, what is the role of BIM in this?

As building professionals, we are particularly sensitive to the impact of our industry on the environment. The building sector alone accounted for 44.9% of the energy consumption in France in 2015*, and 25% of its CO2 emissions come from the energy consumption of buildings during their use**.

The work site itself, the operation of the building and also each component of the building has environmental consequences. According to ADEME (Agency for the Environment and Management of Energy), 7.4 million buildings in France are considered to be “energy sieves”. The impact of a building’s energy consumption is very important. We also must consider the impact of the manufacturing of the products or equipment used, from the extraction of the raw materials necessary for their creation, until their end of life. According to the Test HQE Performance study, building products and equipment account for 56% of building greenhouse gas emissions**.

This figure is cannot be disputed and shows why design and building companies are challenged to do better in selecting building products. But what solutions are available to them? What difficulties do they face? Does BIM provide answers to these issues?

WHAT DO CURRENT REGULATIONS SAY IN TERMS OF BUILDING ENERGY PERFORMANCE?

In France, RT2012 (Thermal Regulation 2012) is mandatory and applies to all building permits. It succeeds RT2005 and precedes RT2020 – each regulation aiming for a 15% improvement in energy performance compared to the previous one.

The Paris Climate Agreement has resulted in new measures to reduce greenhouse gas emissions. As a precursor to future environmental building regulations, RT2020, the E+C- label (Energy Positive & Carbon Reduction) created as a result of this agreement, encourages the construction of energy positive low carbon buildings, for example.

This label includes the calculation of energy and resource consumption over the entire life cycle of the building, from the origin of the materials, through its operation and to the deconstruction of the building. It aims to highlight any difficulties and to feedback previous experience to create the specifications for the new regulations. Until RT2020 comes into force, the label is still completely voluntary.

LCA AND BUILDING PRODUCTS

The standardised evaluation method (ISO 14040 and ISO 14044) for life cycle assessment (LCA) is the most relevant method for assessing the environmental impacts of a system (product, service, company or process) over the entire life cycle. LCA applies in particular to a building, and also to each of its components, product or equipment. This process specifically allows an assessment of the impact on global warming, water and air pollution and the depletion of abiotic resources, but also quantification of the consumption of resources necessary for its production (energy, raw materials and fresh water).

For a manufacturer, LCA is mandatory to be able to generate environmental declarations about its products. These declarations are intended to provide complete and reliable information on building products and equipment and comply with European standard EN 15 804. At the European level, the declaration is called EPD (Environmental Product Declaration). In France, for the building sector this data is grouped together in the form of FDES – Fiches de Déclaration Environnementales et Sanitaires (Environmental and Health Declaration Files) and PEP (Product Environmental Profile).

Since 2017, the FDES and PEP must be audited by an independent third party, recognised by a verification programme agreed by the State. The FDES, verified by INIES (the national reference database on building environmental and health characteristics) includes both an environmental statement and health information on the product. These are multi-criteria and aim to make buildings more sustainable, limiting environmental impact.

PEPs, governed by the PEP ecopassport® programme (the international reference programme to declare the environmental impacts of electrical, electronic and HVAC products) are also environmental statements, but which apply more specifically to the equipment mentioned above.

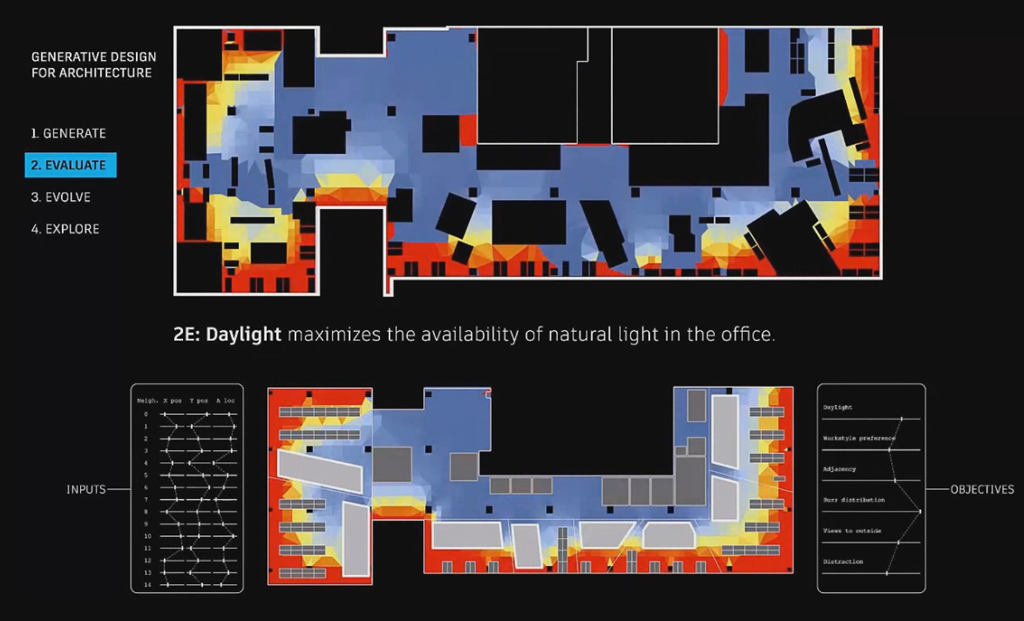

Generative Design Applied on Buildings – Source: BIM Toolbox

THE BUILDING LCA, ESSENTIAL STEP IN OBTAINING AN ENVIRONMENTAL LABEL

The granting of environmental labels, such as HQE (High Environmental Quality), BBCA (Low Carbon Building), Effinergie (Energy-efficient building construction and renovation), E+C- (Positive Energy and Carbon Reduction Building), DGNB (German Sustainable Building Council), BREEAM (Building Research Establishment’s Environmental Assessment Method) and LEED (Leadership in Energy and Environmental Design), also depends on a life cycle analysis being conducted. The acquisition of these labels by companies allows them to be officially recognised on the market and demonstrates their ability to reduce environmental impacts.

LCA can therefore be used as a strategic tool to obtain a label and as a tangible tool for ecological transition.

WHAT IS THE POTENTIAL OF LCA WHEN APPLYING IT TO A CONSTRUCTION PROJECT?

The LCA is especially and above all a tool to compare different scenarios, architectural, for example.

Firstly, the LCA of a building will compare different building design scenarios. The components normally considered at this stage are the volumes of the structure as well as the quantities and types of concrete, wood or steel that are used. Ideally, the LCA can allow architectural choices to be made at an early enough stage.

Still in the design phase, the designer or project owner can then compare the environmental impact of a product or process and anticipate or avoid overconsumption points, be they energy or climate, by selecting products or processes with low environmental impact.

Later, in the execution and operational phases, with more input data the LCA can also be used as a more reliable decision support tool, to make decisions in terms of maintenance for example: ecoresponsible repairs, replacement of equipment with products that consume less energy, renovation of the building in order to delay its deconstruction… However, the impact of these decisions is less than when action is taken upstream. While the ability to perform calculations is more accurate when moving forward in the project, the capacity for action is more limited.

BIM&CO conducted a qualitative study by interviewing experts to identify the main constraints of the building LCA. One of the major problems identified is setting up the evaluation method and especially the collection and centralisation of data, which is extremely important. About 80% of respondents said they find this step arduous and, for 70% of them, this is the biggest issue.

Wissem DEHIMI, chief engineer of sustainable buildings/BIM contact at technical design office Manexi explains: “There is a lack of data on technical equipment that is extremely difficult to satisfy. It would be great to have access to a more complete and richer database“.

One of the LCA and eco-design consultants for the [avniR] by CD2E platform, adds: “Data collection as part of the Life Cycle Inventory (LCI) is proving to be a time-consuming step, as is the creation of viable assumptions for missing input data.“

The second issue raised by our experts is the late implementation of the LCA during construction projects. The various actors involved in the project are then powerless in the face of the choices already made, the calculations made having no real impact on the design choices, and the objectives of the LCA cannot then be achieved. In addition, the analyses are often carried out by people outside the project and not integrated into the project team as such.

Marion SIÉ, President of VERSo, explains: “By allowing earlier access to information, design decisions will be influenced by taking LCA into account. It is therefore essential to be able to perform an LCA as soon as possible and as easily as possible.“

However, there is one last problem that analysts find tiresome: the classification of the components of each product defined depending on the label. The E+C- label perfectly illustrates this issue: the construction products and equipment used must be divided into 13 categories, themselves broken down into sub-categories. This division affects the validity of the standardised energy and environmental study summary (RS2E), and contains a number of parameters to be entered, mainly concerning carbon. This must be included in the technical file that is examined and is used in verifying the consistency of the performance calculation.

DOES BIM ADD VALUE TO THE LCA?

With BIM, the LCA can be performed from the digital model, potentially without even changing the software environment. The BIM LCA should therefore be more automatic, more systematic and simpler to perform. This should allow teams to perform LCAs for different scenarios early in the process and whenever a design or execution choice needs to be made. In the long term, with BIM and generative design, the LCA can be a real benefit in the optimisation of the form and orientation of the building. The expectations for BIM from LCA specialists are very high.

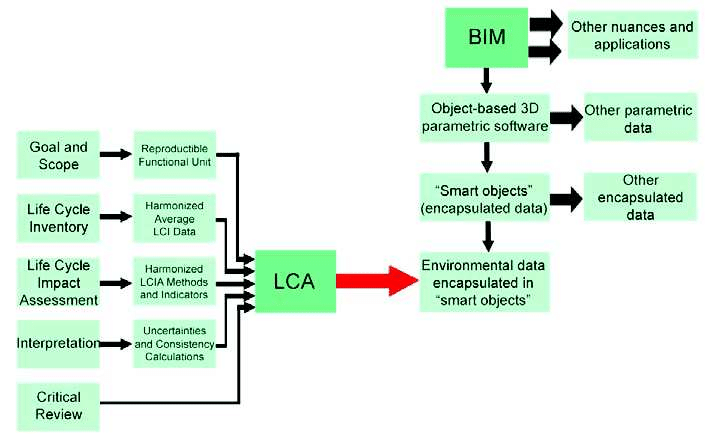

LCA implementation in BIM platform – Source: Márcio Minto Fabricio ****

Today, BIM can become a true LCA asset by facilitating access to both project and component data (whether for finished products or raw materials).

Nevertheless, to date, LCA carried out on the basis of a digital model is still not so easy or systematic. Firstly they are often simplified analyses because of the actual input data coming from the project. These are mostly categories of quantities extracted from the model and integrated into the LCA software that has an environmental database – the LCA is then separated from the model. Some software can also perform the LCA directly in the model, but the assumptions taken into account are still very limited and the databases are not connected. The data taken into consideration is very often limited to the surfaces and quantities of the main materials: concrete, steel and wood. Air conditioning systems and other materials are not taken into account.

This is likely to change very quickly: processes and software will evolve. For BIM&CO, the challenge lies in being able to access environmental data directly within the model.

This is based on current standards and the needs of users for the BIM&CO technology to allow, for example, manufacturers to provide detailed environmental data for their equipment through what are known as BIM objects. To solve the problem related to the classification of components (mentioned above), BIM&CO will also create a classification specific to each environmental label. The centralisation of the environmental data within the object, as well as its label specific distribution into defined categories and sub-categories, allows considerable time savings and aids the work of the actors tasked with obtaining the labels.

BIM&CO technology also allows integration of the FDES and PEP files with the objects managed by public or private platforms, allowing the user to locate reliable and centralised data directly from its BIM software, without re-entry. This represents real time savings when performing life cycle studies.

Today, building LCA is unfortunately not a factor of choice, but more a result. It is still difficult for the actors of a construction project to rely on LCA when making their choices. However, BIM software and solution vendors are playing a significant role in effectively integrating LCA into the digital model, enabling LCA actors to be fully-fledged stakeholders in building design.

Source :

* https://www.ademe.fr/en/particuliers-eco-citoyens/dossiers-comprendre/dossier/lenergie-france/consomme-plus-denergie-france

** http://www.batiment-energiecarbone.fr/IMG/pdf/dossier-presse-label-eprc-2016-11-17.pdf

*** https://autodesk.typepad.com/bimtoolbox/2017/06/generative-design-applied-on-buildings.html

****https://www.researchgate.net/figure/LCA-implementation-in-BIM-platform-Source-AuthorselaborationAuthorselaboration_fig1_311557520